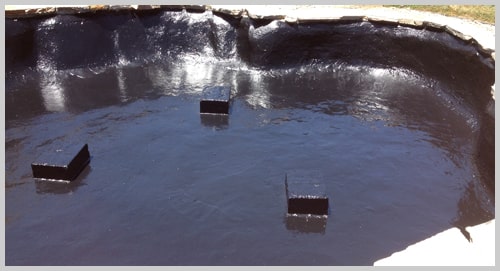

Our pond Sealant NEVER needs a primer and ONLY need one coat. Save time and money !!!

Why Pond Pro 2000?

Rated 4.5 /5 based on 565 customer reviews

Product description: Pond Pro 2000 - Fix Fish Pond and Fountain leaks

- A 25 year history of success

- 5-year warranty

- Lasts 3 TIMES longer than elastomerics or acrylic coatings

- One-coat application

- Withstands seasonal freezes and thaws

- Non-toxic to fish and plants

- UV/Ozone resistant

- Puncture resistant

- Waterproofs within two hours at temps above 55 degrees

- Never worry about seams since it forms a seamless membrane

- Applicable on virtually any surface

- No primers needed

How does PondPro 2000 compare to other products?

| Water resistance | PondPro 2000 is superior to epoxies, urethanes, acrylics, polyesters and alkyds at equal film thicknesses and is not affected by continuous immersion. |

| UV resistance | PondPro 2000 is equal or better than acrylics, polyesters or urethanes and much better than alkyds and epoxies. |

| Temperature tolerance | PondPro 2000 is better than all other coating polymers except silicones. Butyl can withstand live steam as well as cryogenic temperatures. |

| Flexibility | PondPro 2000 is better than all other coating polymers except silicones. Butyl can withstand live steam as well as cryogenic temperatures. |

| Chemical Resistance | PondPro 2000 has very good resistance to strong alkali's, concentrated salt solutions, many acids, and alcohols. |

| Surface tolerance | PondPro 2000 will not bond to a surface that is damp with moisture. PondPro2000 also can be applied directly to metal surfaces that have tightly adhering corrosion without a primer. |

Where can PondPro 2000 be used to its best advantage?

The unique combination of properties which PondPro 2000 possesses can be best utilized when they are applied to the exterior surfaces of stationary structures. Examples are:

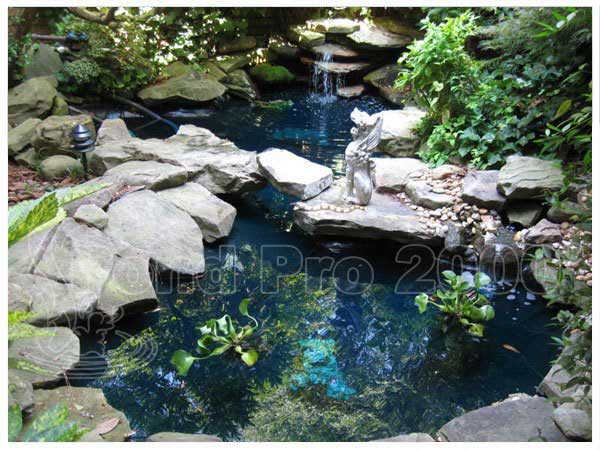

| Ponds and fountains | Concrete fishponds, fountains and reflecting pools are another good application for Butyl. Underwater applications such as these are very demanding and the unique characteristics of Pond Pro have the distinct over other products. |

| Air conditioning drip pans | Excellent moisture barrier and rust inhibitor. |

| Concrete tanks | The excellent waterproofing properties of Butyl will reduce or prevent spalling of concrete in cold climates. |

| Corrosive/humid | Exposed structural steel on the interior of industrial buildings with humid or corrosive environments can be coated with minimal surface preparation. Plating operations, smelters, concrete casting |

| Impoundments | Liquid Butyl are a good choice for exterior spill containment structures because of their excellent weathering and broad chemical resistance properties |